Chemistry

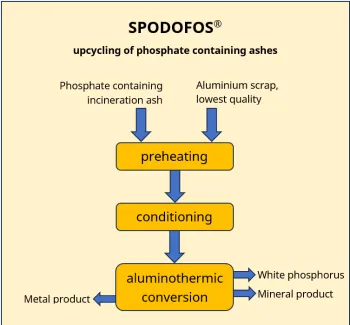

The main reactions of Spodofos are the aluminothermic reduction of phosphate and iron oxides to elemental phosphorus and iron, respectively.

Conversion is strongly exothermic. Phosphate to phosphorus conversion is near complete.

The main reactions of Spodofos are the aluminothermic reduction of phosphate and iron oxides to elemental phosphorus and iron, respectively.

Conversion is strongly exothermic. Phosphate to phosphorus conversion is near complete.

The phosphorus distills from the reactor as P2 gas. At lower temperatures, the P2 gas combines to the well-known P4 gas. At further cooling, it is condensed as white phosphorus, only requiring filtration before shipping. The liquid slag and iron are tapped from the reactor, separated by density difference, and solidified.

Some side reactions occur of which the partly dissolving of P2 gas into liquid iron is of most importance. This solubilization yields ferrophosphorus and lowers the recovery efficiency of the core process. In Spodofos this phosphorus sink will be minimized because of the very high temperature and specific provisions.

Optionally, the lean ferrophosphorus can be treated to harvest the phosphorus content as a valuable phosphate product.

Including postprocessing of ferrophosphorus, overall P-recovery efficiency is very high.

Indeed, sewage sludge ashes can be reduced with (bio)cokes in a traditional electric arc furnace (EAF). The problem is the high concentration of iron oxides in sewage sludge ash. These oxides will be reduced, simultaneously with phosphates, to metallic iron. Phosphorus exhibits a high solubility in liquid iron, leading to a significant loss of P-recovery (up to 40%). That's why the former white phosphorus producer Thermphos (Netherlands, closed in 2012) only co-processed sewage sludge ashes with a very low iron-to-phosphate ratio.

In Spodofos, iron will be reduced as well. This accounts for much of the required energy evolved. However, due to higher temperature compared to EAF and special provisions in the Spodofos process, the phosphorus loss is limited considerably. Therefore Spodofos does not require changes of coagulant at the waste water treatment plants.

Traditional reduction of sewage sludge ash scores low in sustainability. Because of the iron oxides present, this route requires double the electrical energy and leads to a doubling of the CO2-footprint per unit of P-mass when compared to carbon reduction of phosphate rock.

Because the phosphorus gas flow from the reactor is not diluted with carbon monoxide, Spodofos doesn't require feedstock sintering.

Spodofos recovers phosphorus from virtually all ashes and minerals that contain phosphate, such as:

Sewage sludge ashes;

Bone meal ash;

Struvite;

Vivianite;

Sewage sludge char;

Neutralised phosphoric acid waste;

Phosphate rock fines.

Some moisture and/or organic material in the feedstocks is tolerated.

The aluminium to be used can be scrap of the lowest quality. All aluminium alloys and a wide variety of contaminations are allowed.

It's evident, that both phosphate and iron concentration in a feedstock, as well as the aluminium scrap used, affect economy of conversion.

Three products are formed in the Spodofos reactor:

Phosphorus gas, which after condensation and filtration yields valuable white phosphorus;

Slag, which contains a high amount of aluminium oxide (this enables high-end applications);

Metallic fraction, consisting mainly of iron and phosphorus.

White phosphorus (also called yellow phosphorus, elemental phosphorus or P4) is listed by the European Union as a critical raw material. On an industrial scale, white phosphorus has never been recycled from secondary sources only. Its market is demanding.

The slag can be applied as a granulate in high alumina cement and in refractory materials. Other applications are in development.

The metallic product has several direct applications, but can also be processed into a coagulant, for use at waste water treatment plants, and a valuable phosphorus product.

A Spodofos plant is a small plant. The maximum volumetric throughput is the volume of the ash. Additionally, Spodofos comprises few process steps with very low hold-up. This all leads to a limited capex. A Spodofos plant in a base case, with a normal ash gate fee, provides for an attractive payback period. Still, several opportunities can further optimize the business case of the Spodofos process.

Aluminium scrap is the main operational cost. White phosphorus is the main operational revenue. Their market prices are related to eachother by the energy price. Therefore, these prices exhibit a similar historical trend which dampens the economic impact of variations on Spodofos operation.

Only a neglectable part of the aluminium scrap market volume is required. Spodofos plants will not disturb this market.

Sustainability has been assessed independently by CE Delft (www.ce.nl).

For the LCA a base case and a best case in applying the slag are defined: as a gravel for road foundation respectively as a aggregate in refractory materials. In the base case, Spodofos processing saves 1007 kg CO2 per ton of sewage sludge ash*, mostly from avoiding regular production of phosphorus. In the best case, savings are doubled by also avoiding the heat treatment of regular refractory ores.

The answer on the scarcity question "does the use of aluminium scrap justify the production of white phosphorus?" is ambigueous. The currently two available methods on mineral resource scarcity analysis (ReCiPe 2016 Midpoint and CML-IA baseline) show contradictory results.

In these two analyses, only the aluminium-phosphorus consideration was analysed, while not taking into account the impact of high-end slag utilization. If it was taken into account, both answers would be a definite "yes".

All heavy metals are immobilized in the slag or in the metallic product. Leaching tests confirm this. It is expected that PFAS, if present in the feedstocks, will be destroyed at the Spodofos reaction conditions. This assumption will be checked through practice testing later.

The Spodofos core process only requires electricity for mechanical drives and limited thermal energy. This contrasts with traditional phosphorus production where 13MWh electricity per ton P4 is necessary for the reduction process. Spodofos can be designed completely fossil fuel free.

*Data are based on mean Dutch communal sewage sludge ash and are not referenced to another ash treatment method.